.gif)

.gif)

|

Imaging in Developing Countries |

|

Special Interest Group |

|

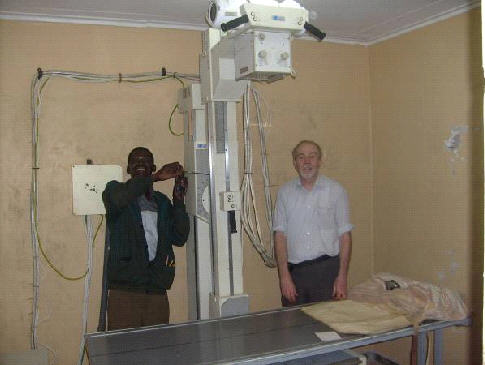

I asked the local technicians to disconnect all the peripheral circuits to the X-ray table and we then put in new fuses. The equipment was switched on and the fuses did not blow but nothing else happened, no displays or lights. Further investigation showed that all the printed circuit boards in the control panel had been pulled out whilst the technicians had been looking for the fault. We switched the equipment off and pushed all the PCB’s back into their slots. The mains was again switched on and the console sprang to life. Displays came on and lights flashed. As all the external wiring to the X-ray room was still disconnected it was apparent that the fault lay in the wiring from the control console to the X-ray room. |

|

We tried to find the fault but unfortunately the wiring was very untidy and also all the same colour with labels made from zinc oxide plaster on the ends. As Malawi is very hot and humid at certain times of the year the labels had faded and some had fallen off. I asked if the hospital had a roll of 1.5mm three core flexible cable so that we could start afresh and rewire the unit. |

|

At this point I realised that this was like asking for the moon. The hospital does not have much in the way of spares and materials due to a lack of finance. Most of their resources go towards patient care. John Challis went off to Mzuzu to try to find some three core and we set about removing the old wiring which was of course recycled by the hospital electrician. The equipment control room and X-ray room each have a junction box and it is these that had to be rewired. We had circuit drawings for the console and the junction box wiring was numbered so that made the rewire easier. John arrived back carrying a roll of 2.5mm three core cable which it transpired was the last and only size available in Mzuzu. |

|

Whilst John had been out looking for the three core cable I set about looking around the X-ray department. The darkroom was very small and the processing of films was carried out using a wet processing system which was probably last used in the mid 70’s in the UK. Fortunately my early training included wet processing so at least I could develop films if the need arose. A similar setup was in place in the previous hospital at Livingstonia. I also found a very small Siemens mobile X-ray machine in a cupboard. When I asked if it worked the radiographer said no. Investigations showed that a fuse had melted. When replaced the unit worked well. I also discovered that the doors to the department were standard interior doors and had no lead protection in them at all. The “lead glass” in the control cubicle was in fact plate glass and afforded no protection. John Challis is arranging for both lead sheet and lead glass to be sent out to Malawi and the local joiners will make lead doors. We believe that the walls provide adequate protection but some measurements are planned to check if this is the case. |

|

Myself, John Gulule and the local electrician set about rewiring the junction boxes wire by wire. Following several hours work we had completed a rewire. We switched on again and this time no fuses blew and the console appeared to work well. Unfortunately when we tried to make an exposure nothing happened. Further investigation showed that the motor in the X-ray tube was not working. We investigated further and found that some wiring was not properly connected and having corrected it the motor worked and we managed to make an exposure. The end of another successful day but we still had a long way to go. |

|

|

.gif)